Manufacturer for China Slant Gasket Pipe Joint Seal Ring ED Ring

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Manufacturer for China Slant Gasket Pipe Joint Seal Ring ED Ring, If you are fascinated in almost any of our solutions or would want to discuss a custom-made order, remember to really feel absolutely free to contact us.

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for China O Ring, Oil Seal, With nearly 30 years’ experience in business, we’re confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

Details

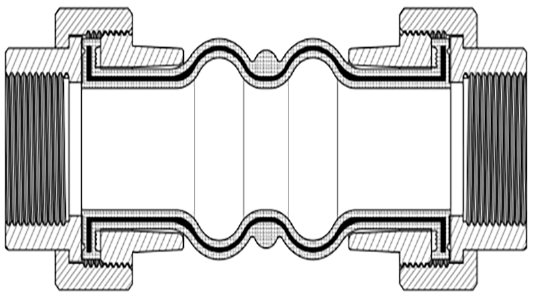

Threaded unions is used When an economical threaded pipe connection is needed, the surface of the union is available both hot-dip galvanizing and electroplating. Both ends provided with a malleable iron union with female thread BS or ANSI.

| Specifications | II | ||

| Working Pressure Mpa (Kgf/Cm2) | 1.6 (16) | ||

| Test Pressure | 2.4Mpa | ||

| Burst Pressure Mpa (Kgf/Cm2) | 4.8 (48) | ||

| Vacuum Kpa (Kgf/Cm2) | 86(660) | ||

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN80 | ||

| Connection Method | THREAD | ||

| Flanges Dimensions | BS, ANSI | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | THREAD | ||

| Flange Material: | MALLEABLE IRON, DUCTILE IRON | ||

| Period of Delivery | about 21 working days | ||

|

Threaded Union (TU) |

||||||||||||||

|

SIZE |

OAL Length |

Allowable Movement-1 |

Dimensions |

Operating Conditions |

||||||||||

|

Nominal Diameter |

Neutral OAL |

Min Installed |

Max Installed |

Max Compressed |

Max Extended |

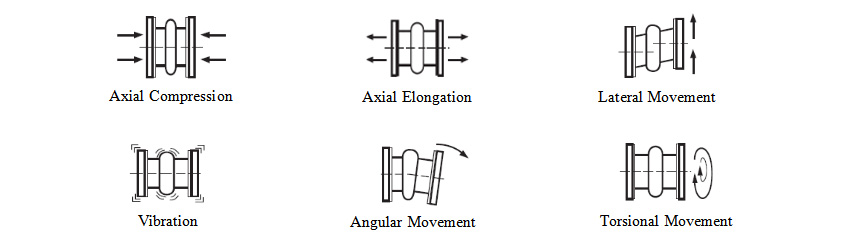

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

OAL Fitting |

OAL Body |

Max w.p. (bar) |

Max Vacuum (in. of Hg)-4 |

|

|

Inch |

mm |

|||||||||||||

|

1/2″ |

15 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

0.92″ |

6.16″ |

150 |

26″ |

|

3/4″ |

20 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

1.00″ |

6.00″ |

150 |

26″ |

|

1″ |

25 |

8” |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±25.3° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/4″ |

32 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±20.7° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/2″ |

40 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±17.5° |

1.35″ |

5.30″ |

150 |

26″ |

|

2″ |

50 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±13.3° |

1.60″ |

4.80″ |

150 |

26″ |

|

2-1/2″ |

65 |

9.6″ |

8.95″ |

9.72″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±10.7° |

2.00″ |

5.60″ |

150 |

26″ |

|

3″ |

80 |

9.6″ |

8.95″ |

9.72′ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±8.9° |

2.00″ |

5.60″ |

150 |

26″ |

|

Threaded Union (TU)-Jis Standard |

||||||||||||

|

Nominal Dia |

Nominal |

Allowable Movements (mm) |

Installation Tolerances (MM) |

OAL Fitting (MM) |

OAL Body (MM) |

|||||||

|

Inch |

mm |

Length (MM) |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

||

|

1/2 |

15 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

3/4 |

20 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 |

25 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 1/4 |

32 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

1 1/2 |

40 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

2 |

50 |

255 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

40 |

175 |

Assume full accountability to satisfy all demands of our consumers; reach ongoing advancements by endorsing the expansion of our purchasers; come to be the final permanent cooperative partner of clients and maximize the interests of clientele for Manufacturer for China Slant Gasket Pipe Joint Seal Ring ED Ring, If you are fascinated in almost any of our solutions or would want to discuss a custom-made order, remember to really feel absolutely free to contact us.

Manufacturer for China O Ring, Oil Seal, With nearly 30 years’ experience in business, we’re confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang